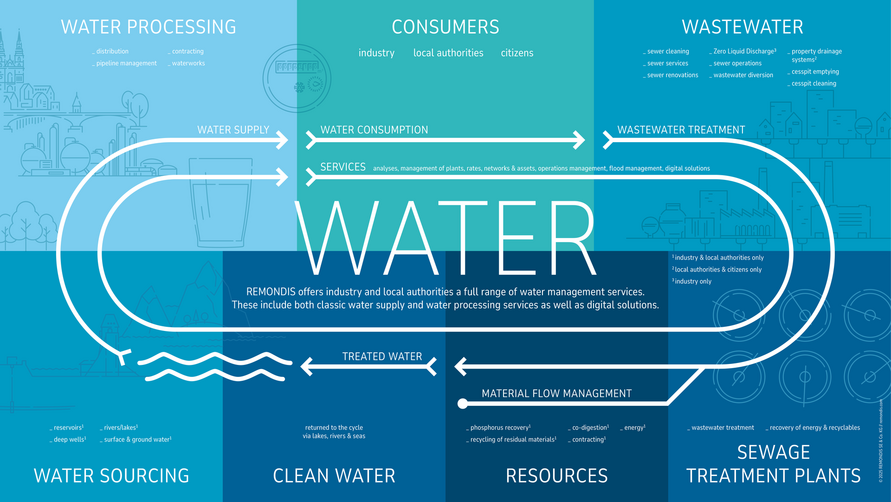

Water is our world’s most important resource – and a scarce commodity in many regions. This is made patently clear by the fact that a mere three percent of the Earth’s water supplies is fresh water. We have devoted ourselves to this three percent and are passionate about protecting it with our comprehensive portfolio of services. From sourcing, producing and supplying drinking water for local authorities and utility companies, to treating their wastewater and recycling their sewage sludge, all the way through to providing all the processes needed to close industrial water cycles. And always with the overriding goals in mind to prevent even the smallest drop of water being wasted on our planet as well as to conserve natural resources by recovering them in the best and most efficient way.

From water to drinking water. Produced by us

Drinking water must first be extracted, processed and distributed before it reaches our taps. We make the most of our experience and technologies to help local authorities and utility companies successfully carry out these tasks. In some cases, as part of decade-long specialist partnerships. These tasks may involve planning, financing and building plants as well as operating them. It all depends on what is needed.

Being a shareholder in ENERVIE, we are jointly responsible for providing a reliable supply of drinking water and maintaining water infrastructure in South Westphalia (Germany). This includes various waterworks, dams, river hydro energy plants and a pumped storage power plant

Nothing remains untreated. Nowhere

There are a whole range of rules and regulations around the world that need to be adhered to when it comes to managing wastewater. Thanks to our expertise, we make sure that these are met – no matter what the laws may be in the different countries. Being a reliable partner, we make sure that municipal, regional and national wastewater treatment goals are reached. Such tasks may involve adjusting plant design and capacities as well as setting up specific treatment stages and adhering to defined wastewater limit values.

Our team in Catalonia (Spain) operates plants able to treat 8,000m³ of water every day. One special feature: the sewage sludge generated by the smaller plants is collected and then dewatered and composted at a central location

Sewage treatment plants – a ‘Jack of all trades’

Modern wastewater treatment does much more than simply clean wastewater. We use synergies that not only make plant operations even more cost-effective but also improve their carbon footprint and conserve natural resources. For example, by generating electricity from the biogas produced by the wastewater treatment processes so that the sewage treatment plants can be energy self-sufficient with their own supply of low-carbon energy. What’s more, we also recover a whole range of raw materials from wastewater. Including phosphorus – an essential element for all forms of organic growth – that we recover from sewage sludge.

Ideally, municipal wastewater treatment systems are also a source of raw materials and energy – helping to improve the carbon footprint of local authorities.

A partner to industry. To close water cycles

Countless industrial businesses around the world benefit from our wastewater treatment expertise. Making the most of our know-how and technologies, we ensure that production plants operating in a wide range of sectors – from chemicals, to automotive, to food processing – have systems installed that enable their used water to be treated on site. Ideally, using zero liquid discharge processes so that their water flows in a closed-loop system and can be immediately reused by the production plant. And all this with resource management as well. Industrial wastewater contains a variety of substances including high-quality salts that we can recover and return to industry for reuse. Furthermore, similar to our municipal portfolio, we also deliver concepts for producing energy that can be integrated into the industrial wastewater treatment systems.

Our team must deliver top-quality wastewater treatment at the industrial facility run by Junca Gelatines in Banyoles (Spain). The wastewater generated by the

gelatine production plant is first treated using chemical/physical processes before being fed into a bioreactor

Our team in Rotterdam (Netherlands) operates a top-quality wastewater treatment facility at the production plant run by Shin-Etsu Chemical, the world’s largest manufacturer of PVC. The composition of the wastewater here is particularly complex and requires both state-of-the-art treatment technology and a high level of expertise

We deploy zero liquid discharge technology to ensure that water is systematically circulated in a closed-loop system – creating production processes with practically no wastewater at all.

The greatest efforts are needed where water is scarce

Water is a precious resource and a number of regions around the world are finding it more and more difficult to get hold of the supplies they need. This is especially true for India – our planet’s most populous country. As a result, Indian authorities have responded by tightening the country’s water management laws to counteract its water scarcity problem. One of the buzz words here is zero liquid discharge. Our teams have been operating in India for many years now helping the country to achieve its mission and building modern wastewater treatment facilities for industrial businesses located there.

Our team in India operates a zero liquid discharge facility in Mumbai for the chemicals manufacturer EVONIK Catalysts. This technology not only helps ensure that practically all of the production water is kept in a closed-loop system but also enables sodium sulphate to be recovered in industrial quality

A reliable partner. No matter how big the network

Besides carrying out classic wastewater treatment tasks on site at our clients’ industrial plants, we also offer a range of other water management services including logistics. There are no limits to the size of project we can take on – as can be seen by the work we provide for a rail logistics firm in Australia. Our contract with this company sees us operating and maintaining all of its water treatment facilities including the pumping stations and oil separators. What’s more, we also carry out laboratory work and water quality checks for them as well.

-

On top down under. One of our team’s tasks in Australia is to handle all water management work for a rail logistics firm that operates across the whole of the country

Experts for what’s left over after wastewater treatment

We take the (sewage) sludge generated by industrial businesses and local authorities and guarantee that it will be recycled in the most environmentally and resource friendly way. And the same is true for infrastructure waste and/or residue generated by wastewater treatment systems (screenings, grit chamber residue, sand from sewers). Our clients not only benefit from our extensive plant capacities here – we can always accept their material regardless of the volume. We also have a range of recycling options for industrial and municipal (sewage) sludge no matter what its composition or how contaminated it may be.

We are a reliable and expert partner for all matters involving the recycling of sewage sludge and the recovery of phosphorus

Flood protection and more. Digitised & sensor-controlled

Digitisation has been in the water management sector for a good while now. We develop bespoke solutions for our customers using both IoT concepts and radio and sensor technology. For example, to create early warning systems in flood prone regions. Furthermore, we make the most of the recorded data to ensure that new-build and plant maintenance projects are planned in the most efficient way possible. However, ‘state-of-the-art’ is not enough for us when it comes to water management. We are also leading the way when it comes to developing solutions for the future. For example, the bio-electrochemical fuel cell, in which microorganisms generate energy by breaking down the organic substances in the water.

Our water management services cover a whole range of tasks – from pump and sewer services, to engineering, all the way through to water chemicals and analytics