Find out more about alternative fuels: Services

Being one of the world’s leading circular economy companies, our core areas of expertise also include recovering raw materials. Our employees work together from their various locations to implement sustainable recycling solutions. Thanks to our global mission, we have become a highly sought-after partner all around the world wherever industrial businesses and local authorities wish to recover and process a wide range of recyclable materials for reuse. Including all relevant related services such as storage systems and logistics.

No collection logistics – No circular economy

We have set up collection and recycling systems at hundreds of locations around the world to help establish a well-functioning recycling economy. As a result, we have become a trailblazer for all countries, local authorities and companies that have set themselves ambitious climate targets and wish to meet zero-waste policies. In Europe and beyond.

Sweden has passed a comprehensive climate action plan and wishes to become a global pioneer in the sustainability sector. Our 50+ business locations there are making some key contributions towards this goal. For example, with our cutting-edge collection and recycling technologies

Material recovery – achieving an extraordinary breadth and depth

Neither our planet nor our consumer society can afford not to recover recyclable materials so they can be reused. Which is why REMONDIS invests a great deal of know-how and capital in recovering valuable materials from different types of waste – even when there are only small amounts or they are particularly difficult to separate. For example, metals from the ash from waste-to-energy plants or phosphorus from sewage sludge ash.

REMONDIS’ subsidiary REMEX operates a recycling plant in Singapore for processing incinerator bottom ash. A lighthouse project, it acts as a role model far beyond Asia’s borders. We developed this technology in Germany and the Netherlands

Whether it be nappy recycling in the Netherlands, coffee pod recycling in Australia or mixed construction waste recycling in the United Kingdom – we have the right solution for everything no matter where it may be.

From recycling to a premium quality raw material

The growing demand from politicians all around the world for greater recycled content in new products has meant that the quality expectations regarding recycled raw materials have grown as well. If, as politicians are calling for, plastic products should be made primarily from recyclate in the future, then the recycled plastic must be of the right quality and have the right level of purity. State-of-the-art plants are required to achieve this – plants that can cleanly separate a wide range of plastics according to type and colour. We develop and operate just such facilities, helping to establish the highest of standards.

We operate a plastics sorting plant in Bochum (Germany), one of the most modern of its kind in Europe. Besides using several different photoelectric sensor stages, the facility also deploys AI

Recycling – using nature as a role model

Not all forms of recycling are simply a question of recovering different materials. In some cases, it also involves taking one type of waste and transforming it into something new – giving it a second valuable use. Just as nature does. We have modelled our organic waste recycling systems on nature’s approach and use these materials to produce both compost and biogas. Both help combat climate change. The first can be used by farmers as a substitute for peat fertiliser, helping to cut carbon emissions. The second promotes the decarbonisation of electricity and the production of alternative fuels.

We operate suitable composting and anaerobic digestion plants wherever our teams are responsible for collecting and recycling organic waste

Thinking of the end so there’s always a new beginning

Being a partner to industry, we work with our customers to develop bespoke recycling solutions. This starts at the earliest possible stage to ensure that their products can actually be recycled: i.e. at the product development stage. Making the most of our ‘Design for Recycling’ expertise, we help manufacturers to think from the end of the life cycle of their products backwards. This enables them to develop and design products where all of the components can be recovered when they reach the end of their useful life. This is the only way to guarantee that the recyclable materials can be processed and reused in the best possible way and that they remain in the respective countries. An important contribution towards reducing dependency on global imports.

Find out more about Design for Recycling: remondis-sustainability.com

-

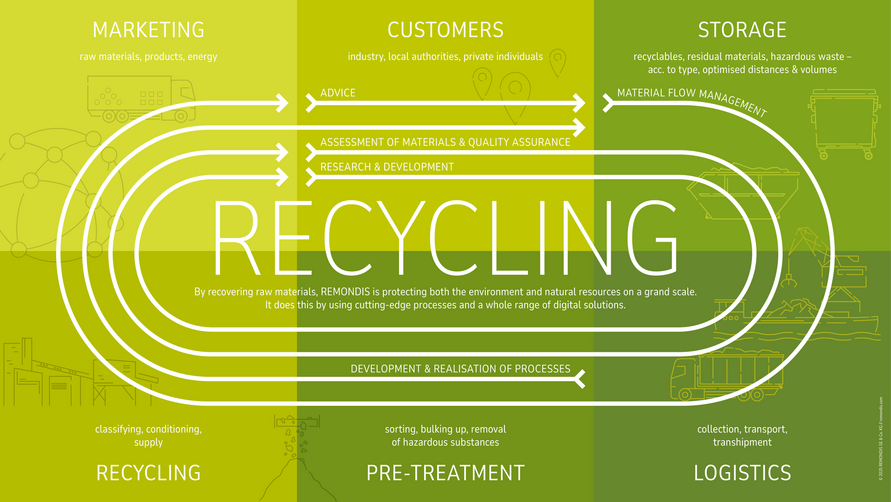

If requested, we advise and support our customers in all areas of material flow management and draw up full-service concepts – from analysing and evaluating materials, to providing storage systems and logistics, through to developing intelligent recycling solutions

It’s not just the output that is important. The input materials are, too

Making products recyclable is a fundamental step towards achieving sustainability. There is a second step, however, that is just as essential, namely using recycled raw materials in new products. Being a producer of high-quality recyclate, we are an important partner to industry in this area as well. We supply manufacturers with large quantities of recycled raw materials, enabling them to make their products without having to use virgin raw materials. This improves the carbon footprint of their products and presents industry with some economic advantages. For example, because it is easier for them to trace the origin of the materials they use as required by the Supply Chain Due Diligence Act and reduces their carbon trading costs.

The greater the recycled content, the better the carbon footprint

of recycled products leave the Lippe Plant every year– including binding agents, biodiesel, certified compost and plastic pellets

REMONDIS’ Lippe Plant – home to the world’s leading recycling innovations

We operate Europe’s largest industrial recycling centre in Lünen (Germany): REMONDIS’ Lippe Plant. Located on the grounds of a former aluminium plant and covering 230 hectares, the Lippe Plant is home to a whole range of different recycling technologies. For example, for processing and recycling gypsum from flue gas desulphurisation systems, chemicals, wood, plastics, e-waste and non-fossil fuels. Every year, 1.0 million tonnes of recycled products leave the Lippe Plant – including binding agents, biodiesel, certified compost and plastic pellets.

Every year, the recycling activities at the Lippe Plant alone enable

Recycling opportunities.

Looked at again and again

Just as is the case with material life cycles, there is, ideally, no end to innovations either. Every single day, our teams at the Lippe Plant and at our many other locations around the world are working on developing an ever greater number of recycling solutions so that an ever greater number of materials can be recycled. In many cases, they come up with ideas and products that go beyond the actual recycling process itself. For example, when we use a residual substance from wastewater treatment to produce a particularly high-quality, eco-friendly white mineral called CASUL. And this is just one example of many cases where our recovery operations have led to novel further developments.

Find out more about our product innovations: remondis-production.de

Our research and development teams are continuously working on innovating recycling systems. For their own locations as well as for the whole of the REMONDIS Group all around the world